WBS @ Westmount

Post Added 07/11/2012

Do you have a Cordless Drill or any other cordless

device that uses NICad battery's that will not hold

charge?

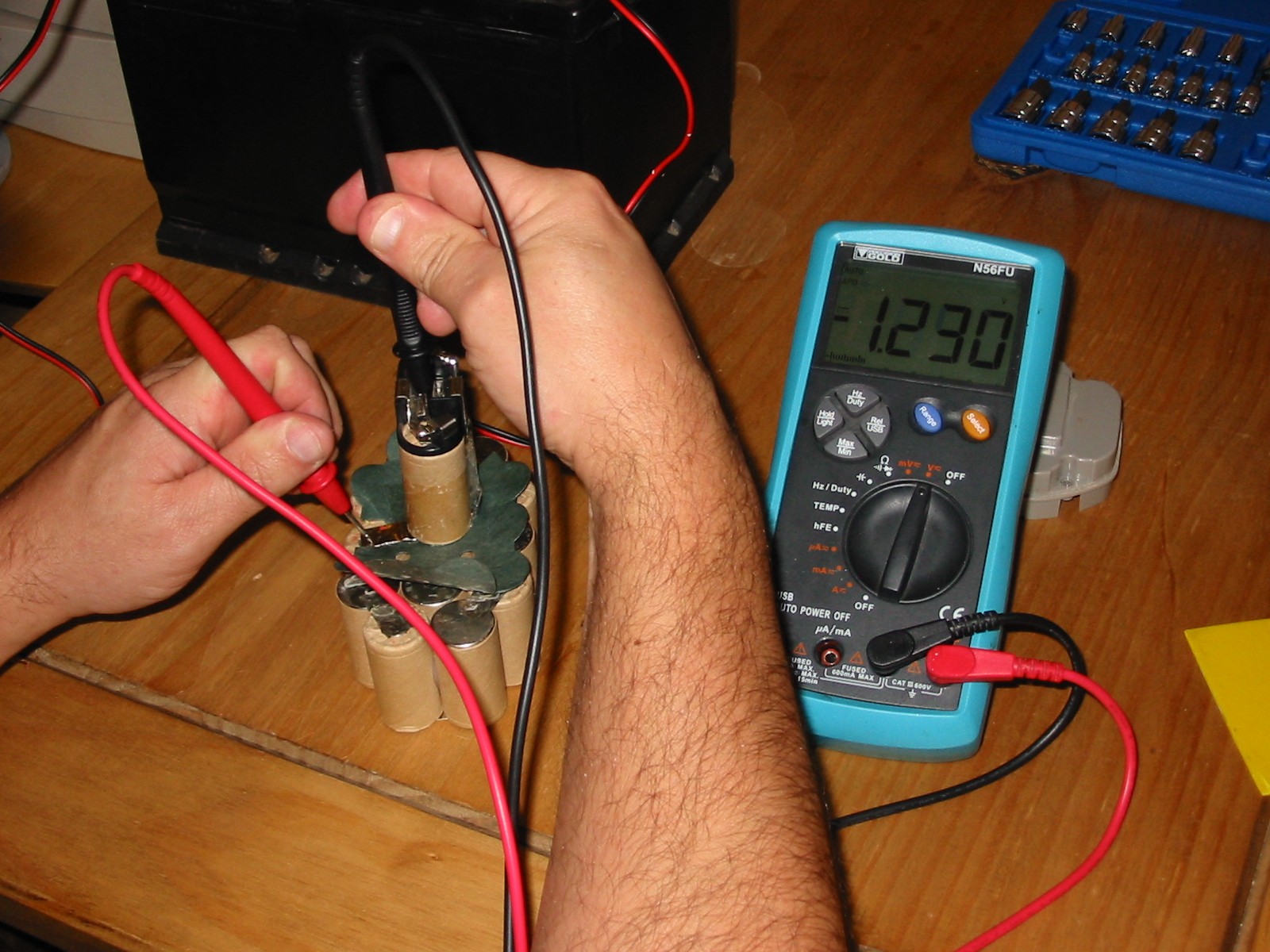

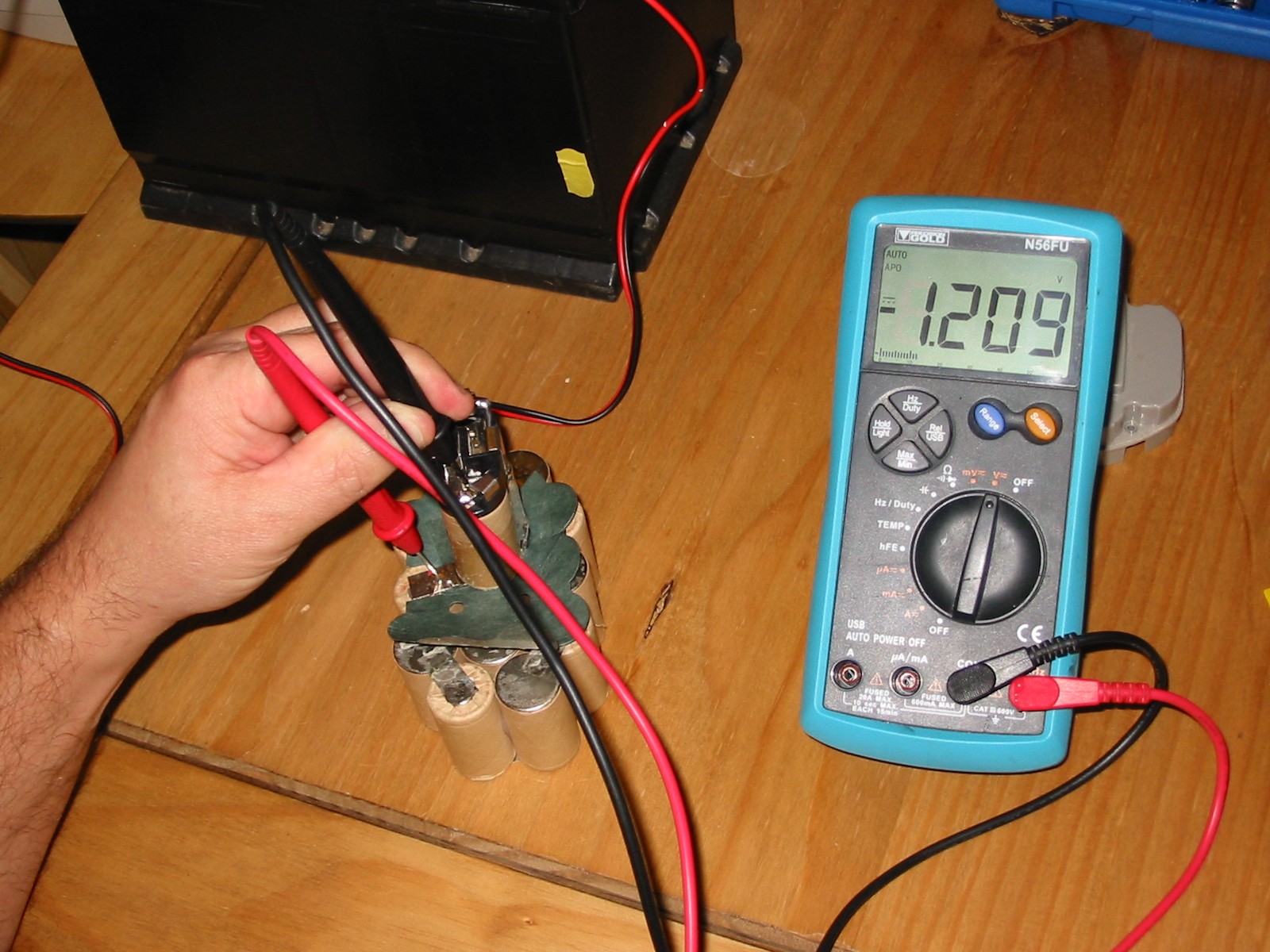

Well this post may just save you some money and restore your Cordless

drill back to a usable condition

What Prompted me to create this post

About 2 years ago i purchased a Makita 8391DWPE 18v.

The tool worked without fault until this year when i noticed the battery's

where noticeably not holding the charge

The drill came with 2 Battery's and a 30 Min Charger and it has always

worked well.

Last Weekend i did some work and due to the one battery only lasting for

about 2 mins from full charge and about 5 mins on the second battery

enough was enough i decided to look for a new drill.

But i was unable to find one that met the specification within a cost i

wanted to pay.

2 Replacement battery's from screwfix would cost me nearly as much as

a new drill with 2 battery's so there was no way i would follow that path

just out of principle.

So what did I do?

Being a practical person i did some research on the Net about Route

cause and fix processes to allow me to understand base information to

allow me to adopt my own DIY Nicad Battery Repair ( Regeneration )

Did My DIY Nicad Fix Work

YES It Did

I will add Pictures and instructions how i turned my dead Makita

8391DWPE 18v into a fully functional unit for free

Full Detail and pictures to be added Weekend 11/11/2012.

Process Walkthrough

1. check voltage of the battery for reference voltage.

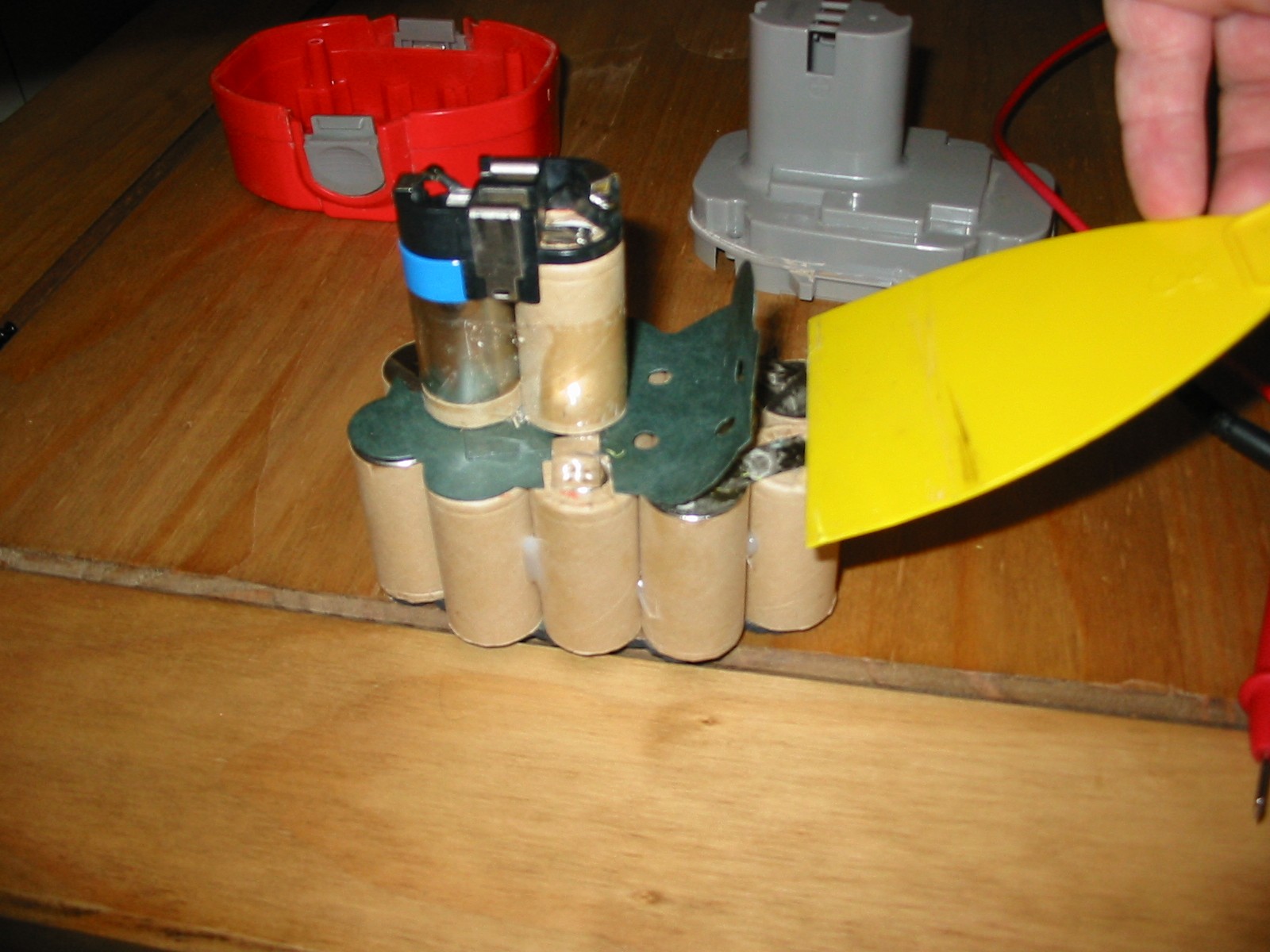

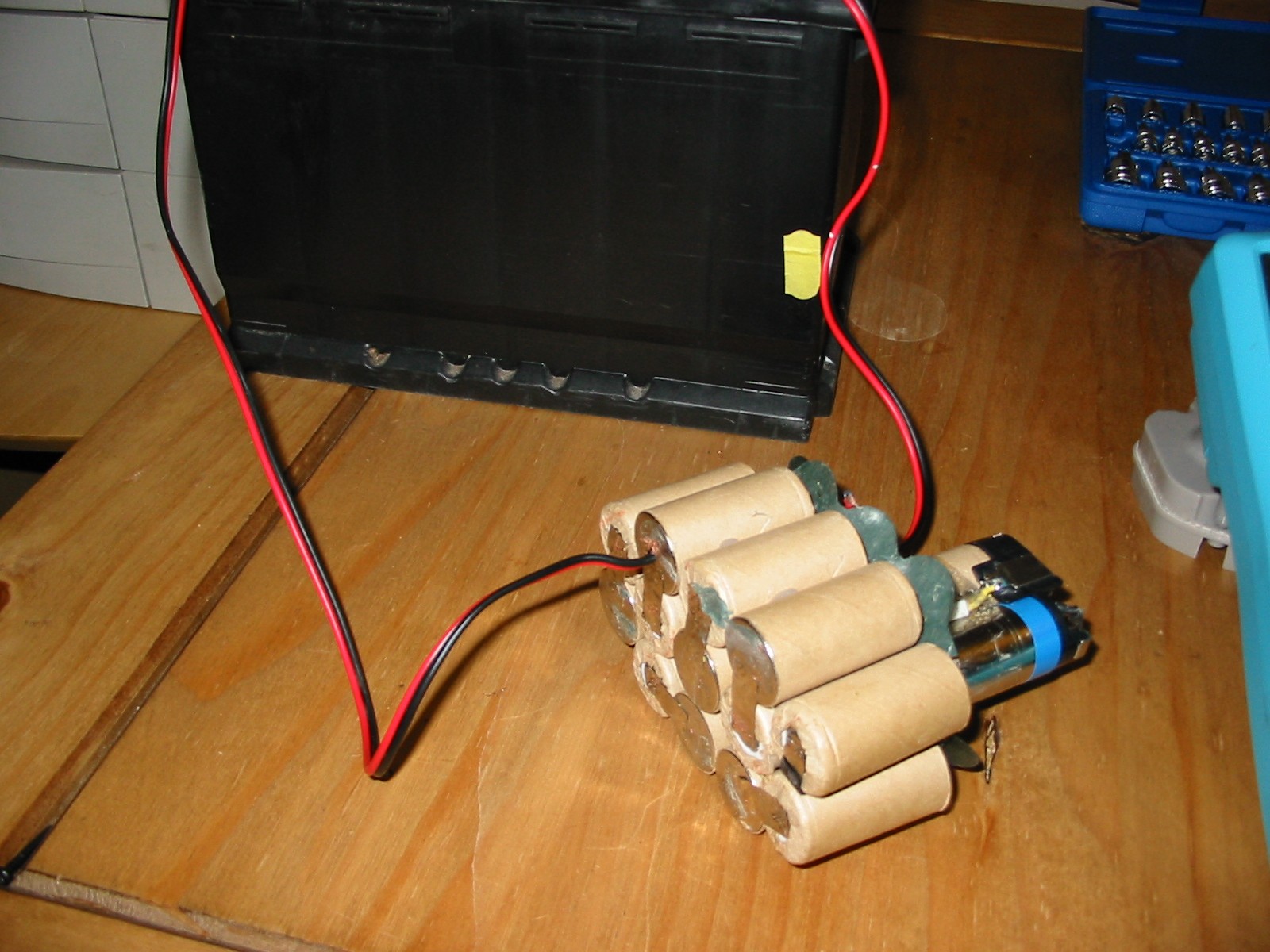

2. Dismantle Battery holder by removing the 4 off Torx Screws T10. Press

the two grey thumb retaining clips and gently pull the grey top top unit

apart from the red base using a rocking action. This will display the Nicad

Module made up of 15 individual 1.2v cells

3. holding the outer edge of the main battery module ( Not the top 2 cells )

gently pull the battery module out of the red lower case.

4. Using a plastic scraper lift the top green insulator card from the top face

exposing the cell electrical connections. ( Do not pull off ). Next repeat the

same process on the bottom of the module but removing the black foam

insulator, again exposing the bottom cell electrical connections.

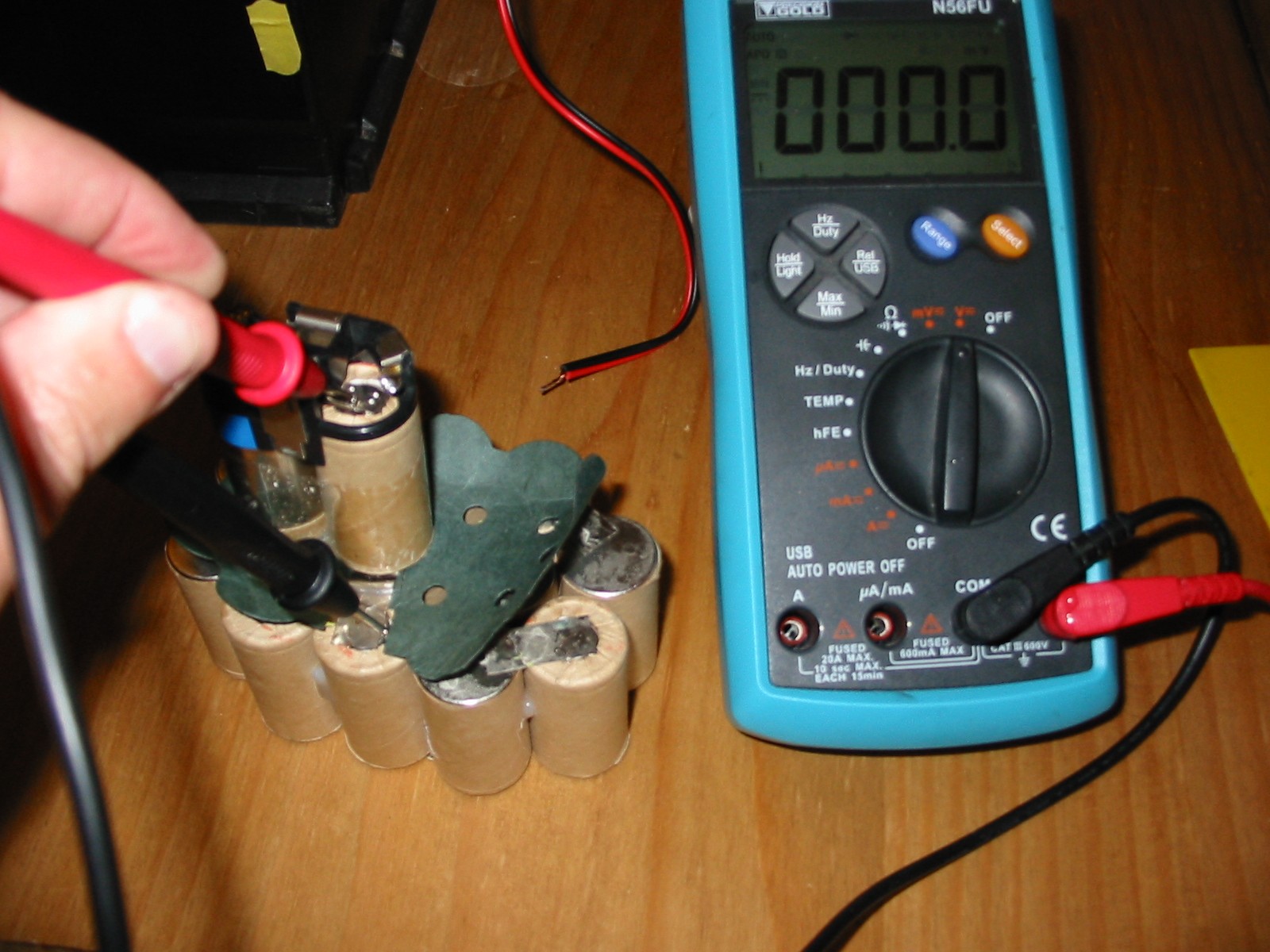

5. At this stage you can check the voltage of each individual Cell and make

note of any cells that are displaying significantly lower voltages.( Mark call

if required with pencil for Reference only )

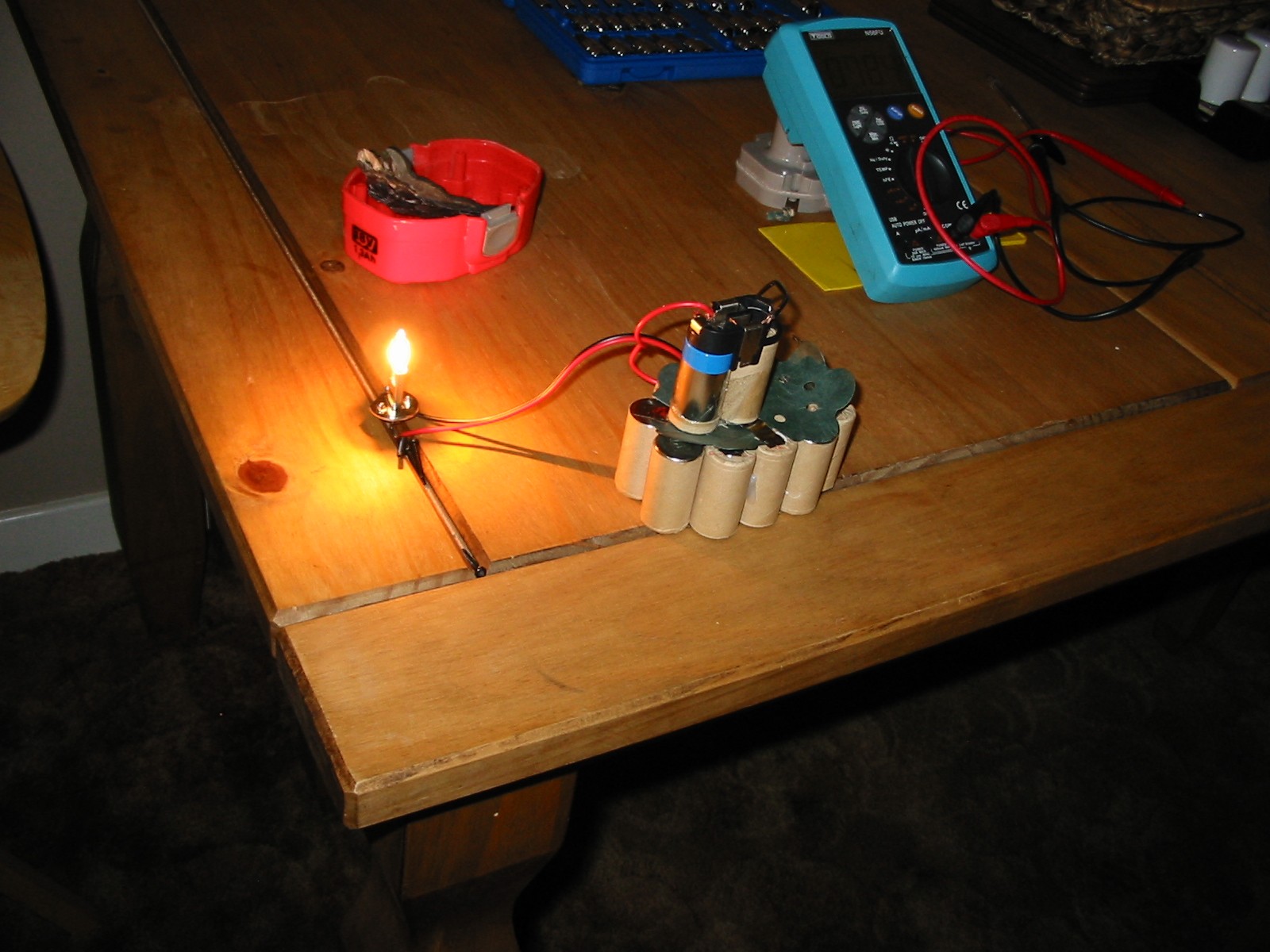

6. The next step was to discharge the complete battery module. I used a car

head lamp bulb placed across the battery pack. I left this on for about 15

Mins to ensure the unit is completely discharged.

7. If the battery contained any significant charge and the battery module is

warm or hot after the discharge process, Place the battery module in the

fridge/freezer for 10mins or so to cool the cells back down.

8. Note the cells are wired in series to generate the 18v so the + and -

orientation is opposite. This is indicated by the small connection being the

positive and the main bottom of the cell being flat Negative. Please check

polarity with the multimeter.

9. When you check the individual cells again you will probably see most of

the cells reporting 1.1v or so but 1 or more of the cells will return 100mv or

even 0V,

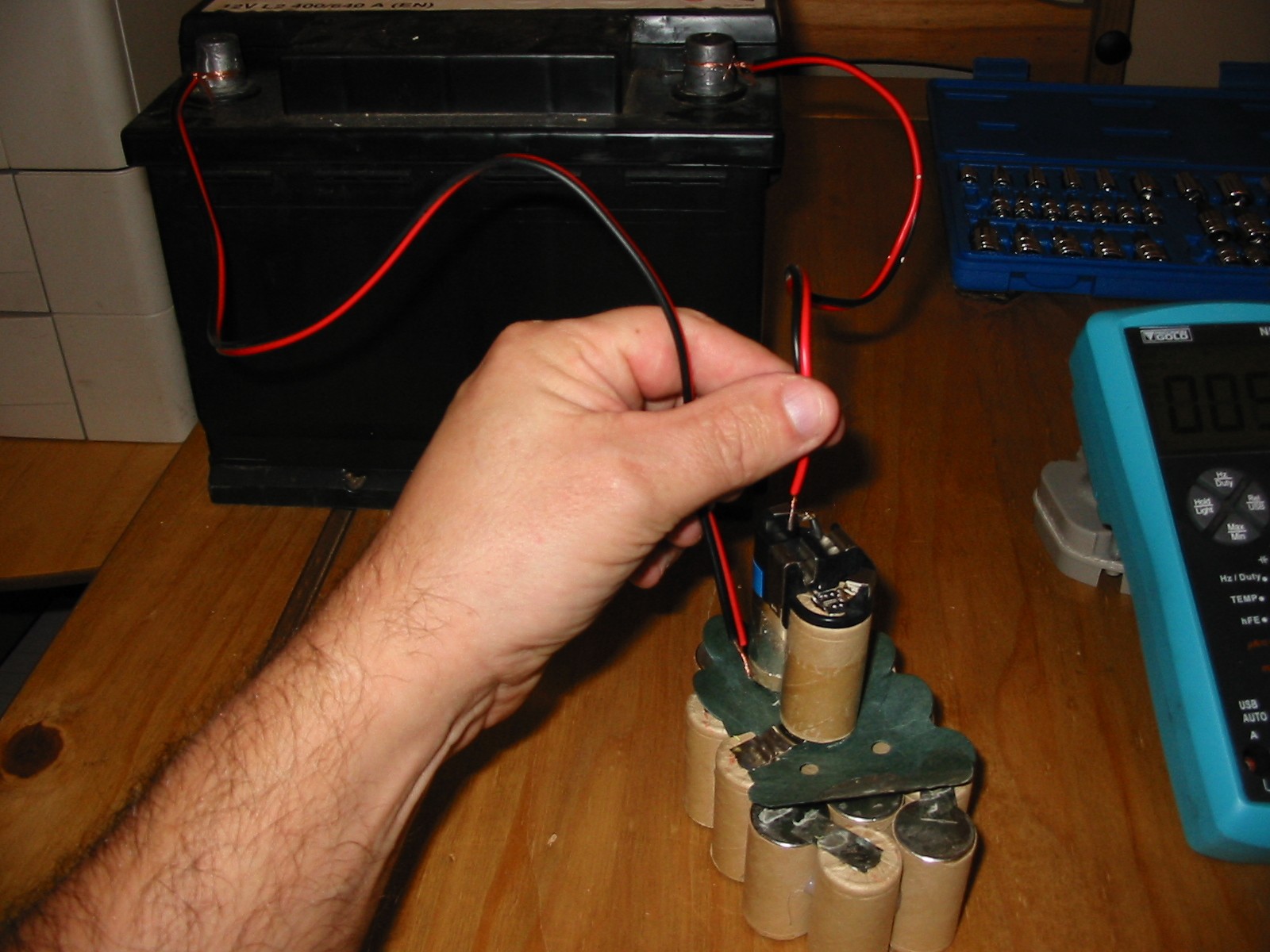

10. Next take the car battery, or similar voltage supply that will withstand

a surge voltage situation, I used a Spare car battery. Note these can pull

well in excess of 100A and will melt car wires very quickly and will catch

fire if left in short circuit contact for more than 1 second or so.

11. Warning ! ( Any actions you take at totally at your own risk, ) This

process has an element of risk, Please use safety gloves and glasses for this

process. What could go wrong? Any of the individual battery Cells could

Explode during the power surge process. The wires from the power source

could melt and burn your fingers if to thin. Power source could be damaged

or explode under surge conditions If you decide to follow any of this

process please be safe and use safety gear to protect yourself.

12. The power shunt process, take two wires from the car battery making

sure the +/- is clearly identified on the wires. This process is the like

striking a match NOT a direct connection of wires to cell.

13. At this point it is very important to ensure you make contact of the

positive wire to the positive battery cell and Negative wire to the negative

Cell. Push one wire onto the cell and strike the other like striking a match

to light it, the end of the wire should spark against the cell. this strike may

be done 2 to 3 times per cell on all 15 cells. You can then repeat this

process for all cells. WARNING! Do not hold the wires directly on the cell

it will likely explode or melt wires. ( It must be a striking action )

14. Check the voltage of all individual cells they should return a minimum

of 1.2v stable on all cells. If any of the cells still look incorrect try another

power surge process on the cell in question. Of you are still unable to

obtain a 1.2V reading on the cell this cell may be scrap and require

replacement.

15. Replace the black insulation foam on the bottom of the module and

push the insulation covering on the top of the module back down. Then

reassemble the battery pack in reverse process of above.

Place the battery pack onto the standard battery charger for the full

charge cycle and test for improvement.